DEDITEC GmbH has developed a control system for a VR Seat Buck on behalf of Prove Realities GmbH. In this interview, Dipl. Ing. Jürgen Siebert, Managing Director of DEDITEC GmbH, explains how the latest customer project was implemented.

Mr. Siebert, the control system for a VR Seat Buck isn’t something you can just develop on the side. Didn’t that take a lot of time?

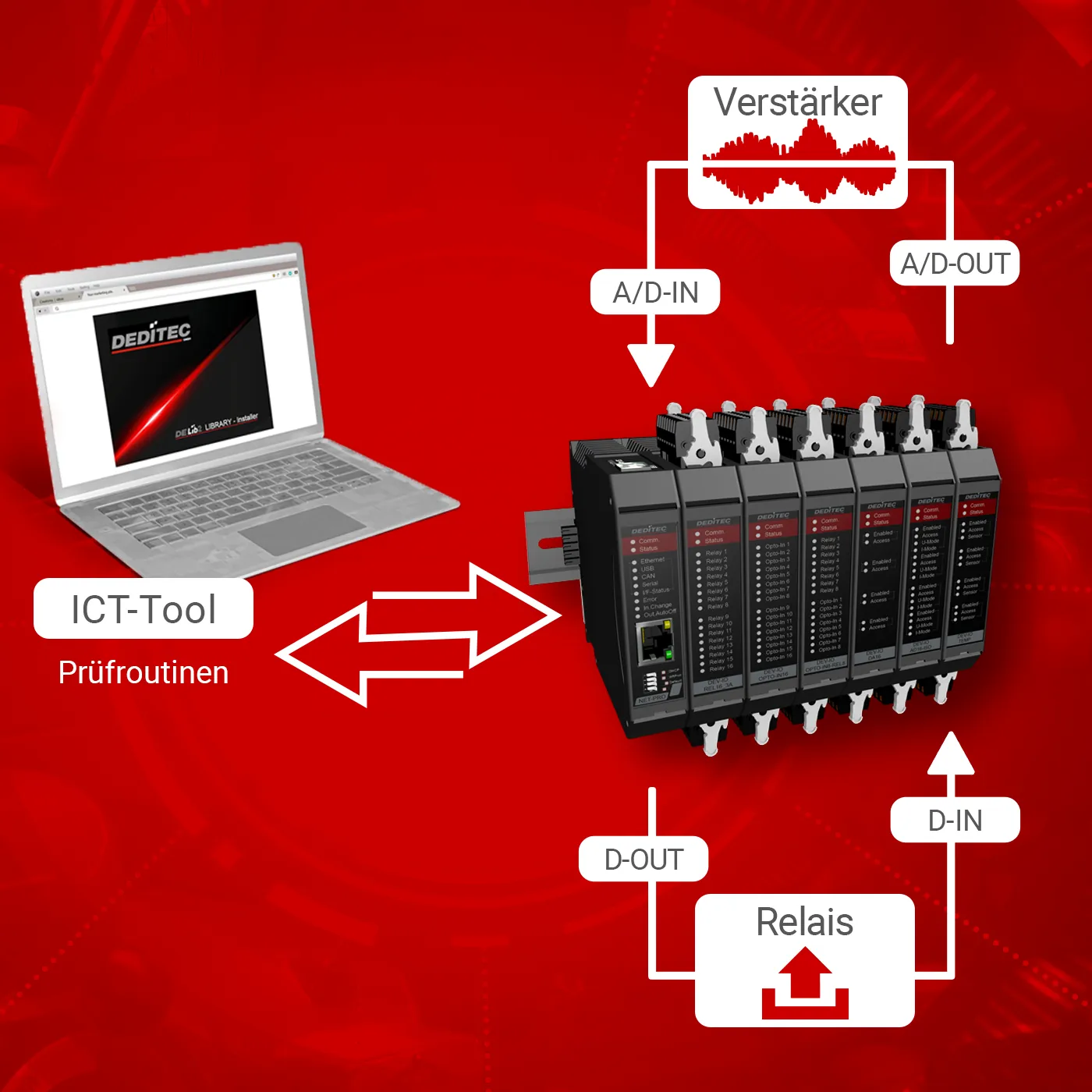

No, of course something like this cannot be done overnight. But fortunately, we already have many highly developed series products that can be adapted for all conceivable applications. For Prove Realities GmbH, we were able to use digital I/O modules from our NET series. The goal was to control and position several electromechanical lifting columns and CAN bus-controlled linear drives using a Windows-supported user interface.

Can you explain that a little more?

By importing specific setup data, Seat Buck can now physically represent different vehicle models.

What does that mean?

The setup data is used, for example, to adjust the height and width of the seat buckle, the seat position including vehicle seat settings, the steering column settings, and the height and width of the armrests.

That sounds like a complex challenge.

It was. In order to optimally combine all components of the system, we developed our own circuit boards with the appropriate connection technology and connected them to each other. The control system and power supply were then installed in two separate 19″ frames.

And that brings me back to your first question: In particular, the complete redevelopment of special circuit boards and mounting plates, which ensure that the system can be dismantled easily and safely, was only possible on schedule thanks to the great teamwork of the well-coordinated DEDITEC team. At times, up to four employees worked on the system. Everything went smoothly here—and despite the strict coronavirus-related hygiene measures, which did not exactly make the work any easier. A big compliment to everyone. Because this enabled us to hand over the project to Prove Realities GmbH on time in the end.

What else was part of your responsibilities within the Seat Buck project?

DEDITEC also took care of all the wiring work on site and manufactured all the necessary cable harnesses. You could say that we gave the Seat Buck its blood vessels and nerve pathways (laughs).

That’s a nice image. Mr. Siebert, thank you very much for talking to us.

Thank you.

For more information on the Seat Buck project, visit: http://www.proverealities.com/