Highlights

- Galvanically isolated CAN interface

- Auto transmit mode

- Auto receive mode

- Support for float values

- Register-based control

- Custom adaptations quick and easy to implement

- Digital and analog input/output units available

- Free firmware updates

- Special connectors for quick module exchange

- Status LEDs

- Detailed documentation

DEDITEC in Brühl now offers an automatic transmit and receive mode for its CAN-controlled I/O modules.

DEDITEC CAN measurement modules with automatic transmit/receive mode

A coordinated combination of hardware and software stands out in the RO-CAN modules from DEDITEC. The galvanically isolated CAN interface, user-friendly Windows configuration software, and over 8 different digital and analog I/O modules provide versatile applications. With the latest update, customers can now also benefit from an automatic transmit and receive mode. Configuration is done via a graphical Windows interface.

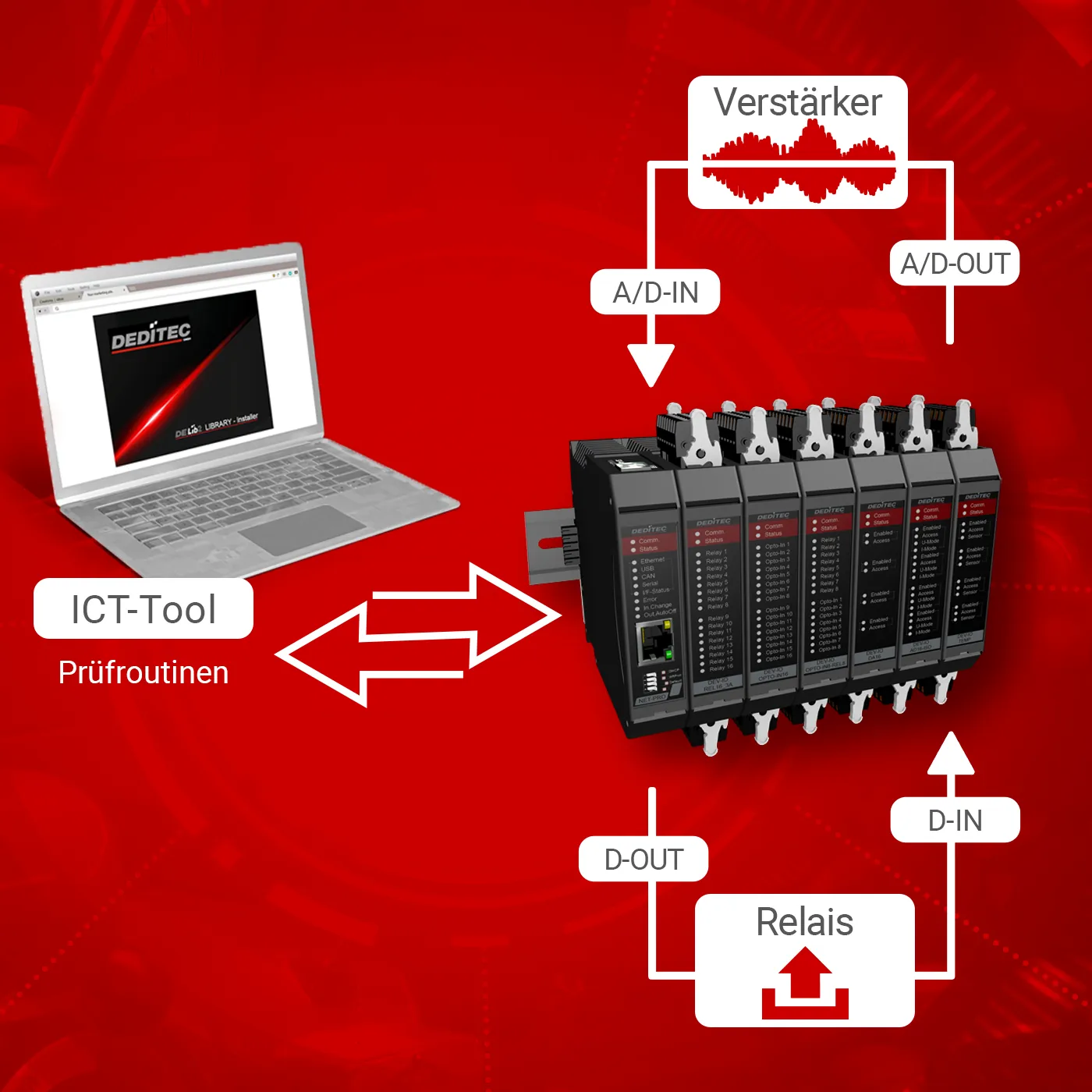

Auto Transmit Mode

Four different transmit packets can be specified, each with a target CAN address and a time interval. The module then automatically sends the configured packets (digital inputs, analog inputs, or test data) at the set interval. The time interval can be adjusted in millisecond steps from 1 ms up to 9 seconds.

Auto Receive Mode

Similarly, four different CAN addresses can be specified. The module reacts to packets sent to these addresses. The user configures what happens with the received data. The CAN data can be output to digital outputs or e.g., to D/A outputs.

Timeout Function

The module also features a timeout function. A time limit can be set in 100 ms steps, within which the module must be addressed. If this does not happen, the timeout activates and all outputs are automatically reset.

CAN Configuration Utility

Installing the driver library also provides a convenient VB configuration tool. This tool allows easy configuration of all settings for automatic sending or receiving, such as baud rate, voltage range, address mode (11 or 29 bit), module/response address, transmit/receive intervals (1 ms to 9 s), and more. Currently, up to four different I/O groups per module can be configured with this tool. Support for float values will soon also be possible.

Custom Implementation

Due to the wide variety of different customer projects and requirements, an “all-in-one” solution is hardly feasible. Our products are therefore designed to allow quick adaptation to specific customer wishes. If you have any questions or problems, please contact us! We are happy to assist you in realizing your project.

Safety and Protection through Galvanic Isolation

In industrial environments, protection through galvanic isolation is essential. The DEDITEC RO-CAN series offers not only the galvanically isolated CAN interface but also all I/O modules with galvanic isolation. These include digital inputs and outputs as well as analog inputs and outputs. The special feature is that the German manufacturer can individually combine the desired I/O units upon customer request.

Documentation and Firmware Updates

Detailed documentation is available in German and English for interested parties and customers as a free download at www.deditec.de