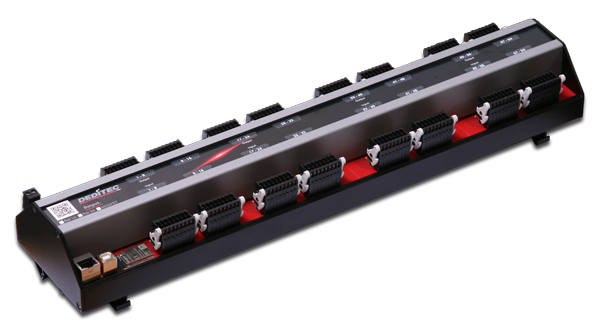

The BS-WEU series is a compact module with an Ethernet and USB interface. In addition, you can integrate and control this module into your PC network via WiFi.

Several different module variants possible

- with 16/32/64/96/128 optocoupler inputs

Optional extensions

- CAN and serial interface (see accessories)

- A/D current mode (see accessories)

- Ethernet interface 10/100 Mbit with electrical isolation

- Connection via WiFi possible

- WPS function

- Open Ethernet protocol

- USB 2.0 interface up to 480 Mbit

- Digital inputs: 15V – 30V AC/DC (optional 5V – 15V)

- 16 bit counter (up to 100Hz) / flipflop per channel

- Sturdy aluminum housing (suitable for top-hat rail mounting)

WEU Modules

WEU Modules (WEU= WiFi, Ethernet, USB) can be connected to the PC network via Ethernet or USB interface, but also via WiFi. For a more user-friendly connection setup via WiFi, the module can also be connected to the router via WPS function.

Digital inputs

With our optocoupler inputs, digital signal states can be recorded within a voltage range of 5V to 30V AC or DC. Input and output circuits are galvanically isolated from each other up to 2.5kV.

Digital In Input Filter

With our Digital-In modules, an input filter can be set in a time interval of 1ms…255ms to filter interference pulses.

This means that AC signals can also be detected cleanly.

Counter

Each input has a 16 bit counter that can count up to 65535 pulses. If the maximum counter value is exceeded, the counting process starts again from zero. By means of a software command, the current status of all input counters can be read from the module simultaneously.

Recording of status changes

Status changes that occur between the readout cycles are reliably detected by internal flip-flops and can be read out separately by software. In addition, such an event is signalled by a status LED. Resetting is done automatically after the flip-flops have been read out.

LEDs

Each digital input and output has a separate LED that lights up when the signal state is active. Furthermore, the status of the operating voltage, the communication with the interface, error events or the occurrence of a timeout can be displayed.

Connectors

A screwless system from the manufacturer WAGO Kontakttechnik is used as the connector. The 1-wire female connectors are 100% protected against mismating and have an eject and locking mechanism. All conductor types up to 1.5mm² can be connected.

Remote switching of IP modules

Our IP modules can be conveniently and easily controlled from home anywhere in the world via the TCP-IP network. The following free options are available to you for this purpose.

ICT-Tool:

Our ICT-Tool is included in the DEDITEC driver library. With the help of this software, you can configure, control and test your DEDITEC modules.

DEDITEC I/O-Control App:

Configure your DEDITEC modules easily via smartphone. With our DEDITEC I/O Control app, our modules can also be controlled while on the move.

Weboberfläche:

Our IP modules can be operated from any browser. All you need is the IP address of the module.

Reviews

There are no reviews yet.